“Should we start with Cascade?”

It’s fitting that our founder, Ken Grossman, would make that suggestion while in Yakima, Washington, earlier this month for hop selection. He’s been smitten with whole-cone Cascade hops since first taking in their grapefruit and pine aromas in the late ’70s. (They’re the staple of our flagship Pale Ale.) Back then, when Sierra Nevada was but a young idea in his mind, Ken couldn’t afford hops in bulk; he did, however, take home stacks of “brewers cuts,” one-pound blocks of whole-cone hops that brewers inspected for quality to inform purchases.

Ken quickly moved to the other side of the brewers-cut coin, and this year he scrutinized them alongside a seasoned team: 30-year head brewer Steve Dresler, 28-year veteran brewer Bart Whipple, 17-year research analyst Ruth Martin, and 9-year raw materials manager Tom Nielsen. Over several days in Washington and Oregon, the crew rolled in a Dodge mini-van, cruising almost nonstop to visit premier hop suppliers that pepper the two states. (The car rental company surely marveled at the, uh, resinous scent embedded in the seats upon its return.)

At each stop, they were met with brewers cuts of different varieties—among them Cascade, Magnum, Centennial, Sorachi Ace and Simcoe. (Of the latter, Bart at one point proclaimed, “…all I smell right now is cat pee.”) The hop “exam” is straightforward: tear a handful of hops from the cut, rub them in your hands to warm them up and activate the essential oils, and put that palmful of awesomeness to your nose. Booming aroma? Off scents? Too “green” (premature picking)? With the collective experience of Ken and his team, decisions were rapid and indisputably confident—mind you, in some cases these are calls on tens of thousands of pounds of hops. We average around one pound of whole-cone hops per barrel of beer, and we’re approaching an annual production of 1 million barrels. You could say we like the ingredient.

Our team’s decisions weren’t uniformly favorable, though; it took persistence to discover the best crops. The hop industry faced challenges this season. Much like how weather compromised our estate barley, unexpected, early season heat and recent rain taxed hop fields in the Pacific Northwest, namely Oregon. Heat tricked some hop cones into blooming prematurely, which forced farmers to trim them back to start anew, ultimately changing the hop maturity timeline. Relentless rain and wind in some instances literally crippled fields; imagine the heartache of watching 100+ acres of trellises collapse. We spoke to one farmer who had to pause harvesting amid the rain, causing a 50-acre production loss, or more than 100,000 pounds of hops.

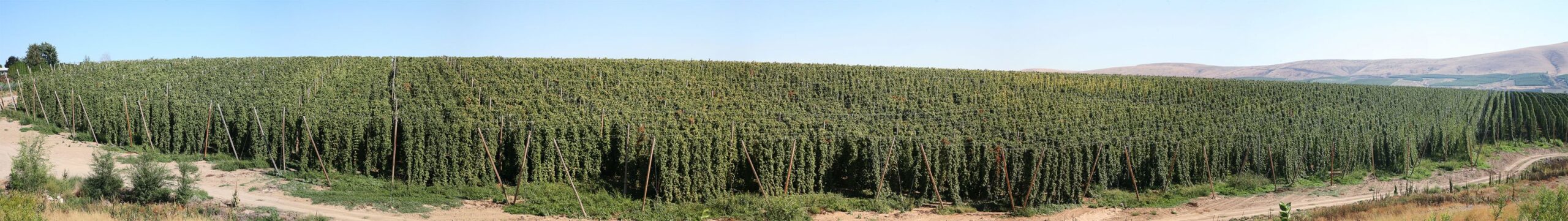

As you may have started gathering, the scale of the hop industry is impressive. Really all it takes is a car ride between Yakima and Moxee, Washington, to understand its magnitude. Tall, dense, lush fields of hops are everywhere. At last count, farmers strung 35,000 acres of the crop on trellises for the 2013 harvest. It’s a big number, yes, but that’s divvied up among more than 2,500 American craft breweries and plenty of international brewing talent clamoring for stateside aromatic varieties. Further, craft beer sales are soaring, giving the evolution of the hop game even more weight.

It’s an evolution in which we’ll be active, from championing new, mind-blowing hop varieties to challenging production best practices. Stay tuned for another harvest-inspired post about the kiln drying of hops. It’s a critical step we think can be manipulated to achieve exciting, varying results, and our own Tom Nielsen conducted tests while in Yakima.